Page 6 - SD 2507

P. 6

Filler materials and shielding gases guaranteeing PREN > 40 have been

developed (wire, metallic cored wire, electrodes) - a list of tested filler materials is

available on request.

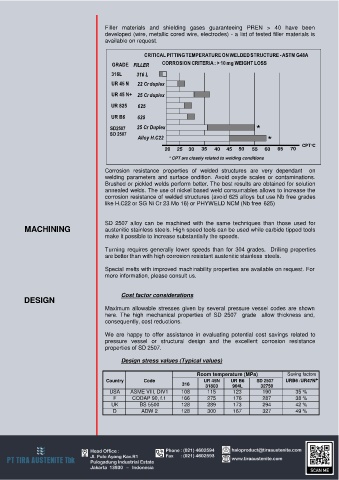

CRITICAL PITTING TEMPERATURE ON WELDED STRUCTURE - ASTM G48A

GRADE FILLER CORROSION CRITERIA : > 10 mg WEIGHT LOSS

316L 316 L

UR 45 N 22 Cr duplex

UR 45 N+ 25 Cr duplex

UR 825 625

UR B6 625

SD2507 25 Cr Duplex *

SD 2507

Alloy H.C22 *

20 25 30 35 40 45 50 55 60 65 70 CPT°C

* CPT are closely related to welding conditions

Corrosion resistance properties of welded structures are very dependant on

welding parameters and surface ondition. Avoid oxyde scales or contaminations.

Brushed or pickled welds perform better. The best results are obtained for solution

annealed welds. The use of nickel based weld consumables allows to increase the

corrosion resistance of welded structures (avoid 625 alloys but use Nb free grades

like H.C22 or SG Ni Cr 23 Mo 16) or PHYWELD NCM (Nb free 625)

SD 2507 alloy can be machined with the same techniques than those used for

MACHINING austenitic stainless steels. High speed tools can be used while carbide tipped tools

make it possible to increase substantially the speeds.

Turning requires generally lower speeds than for 304 grades. Drilling properties

are better than with high corrosion resistant austenitic stainless steels.

Special melts with improved machinability properties are available on request. For

more information, please consult us.

DESIGN Cost factor considerations

Maximum allowable stresses given by several pressure vessel codes are shown

here. The high mechanical properties of SD 2507 grade allow thickness and,

consequently, cost reductions.

We are happy to offer assistance in evaluating potential cost savings related to

pressure vessel or structural design and the excellent corrosion resistance

properties of SD 2507.

Design stress values (Typical values)

Room temperature (MPa) Saving factors

+

Country Code UR 45N UR B6 SD 2507 URB6 /UR47N

316 31803 904L 32750

USA ASME VIII, DIV1 108 115 123 190 35 %

F CODAP 90, f.1 166 275 176 287 38 %

UK BS 5500 128 289 173 294 42 %

D ADW 2 128 300 167 327 49 %