Page 4 - SA 316

P. 4

A post-weld heat treatment is not necessary.

Preheating and post heating are not necessary.

200°C (392°F) is the maximum interpass temperature. Post-weld pickling and

passivation treatment are necessary.

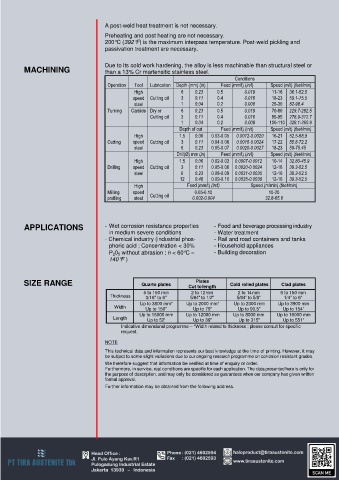

MACHINING Due to its cold work hardening, the alloy is less machinable than structural steel or

than a 13% Cr martensitic stainless steel.

Conditions

Operation Tool Lubrication Depth (mm) (in) Feed (mm/t) (in/t) Speed (m/t) (feet/min)

High 6 0.23 0.5 0.019 11-16 36.1-52.5

speed Cutting oil 3 0.11 0.4 0.016 18-23 59.1-75.5

steel 1 0.04 0.2 0.008 25-30 82-98.4

Turning Carbide Dry or 6 0.23 0.5 0.019 70-80 229.7-262.5

Cutting oil 3 0.11 0.4 0.016 85-95 278.9-312.7

1 0.04 0.2 0.008 100-110 328.1-360.9

Depth of cut Feed (mm/t) (in/t) Speed (m/t) (feet/min)

High 1.5 0.06 0.03-0.05 0.0012-0.0020 16-21 52.5-68,9

Cutting speed Cutting oil 3 0.11 0.04-0.06 0.0016-0.0024 17-22 55.8-72.2

steel 6 0.23 0.05-0.07 0.0020-0.0027 18-23 59-75.45

Drill(Ø) mm (in) Feed (mm/t) (in/t) Speed (m/t) (feet/min)

High 1.5 0.06 0.02-0.03 0.0007-0.0012 10-14 32.80-45.9

Drilling speed Cutting oil 3 0.11 0.05-0.06 0.0020-0.0024 12-16 39.3-52.5

steel 6 0.23 0.08-0.09 0.0031-0.0035 12-16 39.3-52.5

12 0.48 0.09-0.10 0.0035-0.0039 12-16 39.3-52.5

High Feed (mm/t) (in/t) Speed (m/min) (feet/min)

Milling speed 0.05-0.10 10-20

profiling steel Cutting oil 0.002-0.004 32.8-65.6

APPLICATIONS - Wet corrosion resistance properties - Food and beverage processing industry

in medium severe conditions

- Chemical industry (industrial phos- - Water treatment

- Rail and road containers and tanks

phoric acid ; Concentration < 30% - Household appliances

P 2 0 5 without abrasion ; < 60°C – - Building decoration

140°F )

SIZE RANGE Quarto plates Plates Cold rolled plates Clad plates

5 to 150 mm Cut to length 2 to 14 mm 6 to 150 mm

2 to 12 mm

Thickness 3/16" to 6" 5/64" to 1/2" 5/64" to 5/8" 1/4" to 6"

Up to 3800 mm* Up to 2000 mm* Up to 2300 mm Up to 3900 mm

Width Up to 150" Up to 79" Up to 90.5" Up to 154"

Length Up to 16000 mm Up to 12000 mm Up to 8000 mm Up to 16000 mm

Up to 52'

Up to 551"

Up to 315"

Up to 39"

Indicative dimensional programme – *Width related to thickness ; please consult for specific

request.

NOTE

This technical data and information represents our best knowledge at the time of printing. However, it may

be subject to some slight variations due to our ongoing research programme on corrosion resistant grades.

We therefore suggest that information be verified at time of enquiry or order.

Furthermore, in service, real conditions are specific for each application. The data presented here is only for

the purpose of description, and may only be considered as guarantees when our company has given written

formal approval.

Further information may be obtained from the following address.