Page 2 - SA 316

P. 2

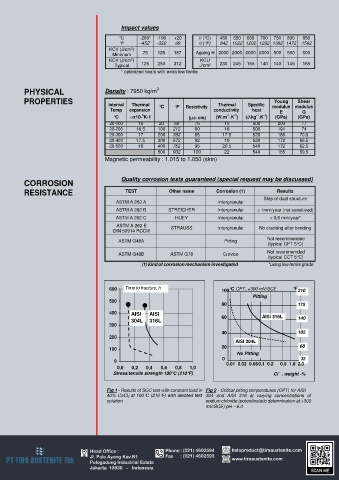

Impact values

°C -269* -196 +20 (°C) 450 550 650 700 750 800 850

°F -452* -320 68 (°F) 842 1022 1202 1292 1382 1472 1562

KCV (J/cm²)

Minimum 75 125 187 Ageing H 2000 2000 2000 2000 500 500 500

KCV (J/cm²) KCU

Typical 125 250 312 J/cm² 230 245 155 140 140 145 165

* optimized heats with extra low ferrite

3

PHYSICAL Density : 7950 kg/m

PROPERTIES Interval Thermal Thermal Specific Young Shear

Temp expansion °C °F Resistivity conductivity heat -1 modulus modulus

G

E

6

-1

-1

-1

°C

20-100 x10- K-1 20 68 (µ cm) (W.m .K ) (J.kg .K ) (GPa) (GPa)

15

200

16

75

77

500

20-200 16.5 100 212 80 17.5 500 194 70.5

74

16

20-300

186

200

17

85

392

520

20-400 17.5 300 572 92 19 530 172 66.5

95

20-500 18 400 752 100 20.5 540 172 62.5

500

165

540

22

932

59.5

Magnetic permeability : 1.015 to 1.050 (skin)

CORROSION Quality corrosion tests guaranteed (special request may be discussed)

RESISTANCE TEST Other name Corrosion (1) Results

Step of dual structure

ASTM A 262 A Intergranular

ASTM A 262 B STREICHER Intergranular 1mm/year (not sensitived)

ASTM A 262 C HUEY Intergranular < 0,6 mm/year*

ASTM A 262 E STRAUSS Intergranular No cracking after bending

DIN 50914 RCCM

Not recommended

ASTM G48A Pitting

(typical CPT 5°C)

Not recommended

ASTM G48B ASTM G78 Crevice

(typical CCT 5°C)

(1) kind of corrosion mechanism investigated *using low ferrite grade

600 Time to fracture, h 100 °C CPT, +300 mV/SCE °F 210

Pitting

500

80

400 AISI AISI

304L 316L 60 AISI 316L 140

300

40 105

200

AISI 304L 68

100 20

No Pitting

0 0.01 0.02 0.05 0.1 0.2 0.5 1.0 2.0

0,0 0,2 0,4 0,6 0,8 1,0

Stress/tensile strength 100°C (210°F) Cl , weight -%

-

Fig 1 - Results of SCC test with constant load in Fig 2 - Critical pitting temperatures (CPT) for AISI

40% CaCl 2 at 100°C (210°F) with aerated test 304 and AISI 316 at varying concentrations of

solution sodium chloride (potentiostatic determination at +300

mV/SCE) pH 6.0