Page 1 - SA 316

P. 1

PRODUCT DATA SHEET

Corrosion Stainless Steel

AUSTENITIC STAINLESS STEEL GRADE

SA 316 is one of the basic grade of the stainless steels range. 2% Molybdenum

bearing ensures better corrosion resistance than SA 304 grade, particularly

regarding to uniform and localized corrosion.

Alloy SA 316 is an austenitic microstructure grade, free of deleterious carbide

precipitations in grain boundaries. The grade contains some residual ferrite (˜ 3%)

after solution annealing (1050-1150°C – 1922-2102°F) and water quenching.

Chemistry and heat treatments may be optimized in order to control the ferrite

content.

SA 316 steel resists to wet atmosphere or room temperature solutions containing

some chloride or fluoride additions. The steel is not seawater resistant. The alloy

may be used in diluted sulphuric acids at low temperature ( 330°C - 626°F) as

well as in sour organic solutions.

The grade is also well known for its higher ductility, particularly when considering

cold forming

STANDARDS EURONORM .............................. 1.4404 X2CrNiMo 17.12.2

AFNOR ...................................... Z3 CND 17-11-02

DIN ............................................... W1.4404

ASTM. ........................................ A 240 TP 316L

UNS S31603

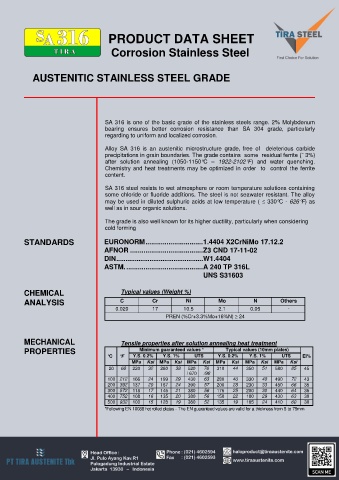

CHEMICAL Typical values (Weight %)

ANALYSIS C Cr Ni Mo N Others

10.5

2.1

0.020 17 PREN (%Cr+3.3%Mo+16%N) 24 0.05 -

MECHANICAL Tensile properties after solution annealing heat treatment

PROPERTIES Minimum guaranteed values * Typical values (10mm plates)

°C °F Y.S. 0.2% Y.S. 1% UTS Y.S. 0.2% Y.S. 1% UTS El%

MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi

20 68 220 32 260 38 520 76 310 44 350 51 580 85 45

/ 670 /98

100 212 166 24 199 29 430 63 280 40 330 48 490 72 43

200 392 137 20 167 24 390 57 200 28 230 33 450 66 35

300 572 118 17 145 21 380 56 175 25 200 30 440 64 35

400 752 108 16 135 20 380 56 150 22 180 29 430 63 30

500 932 100 15 128 19 360 52 135 19 165 24 410 60 30

*Following EN 10088 hot rolled plates - The EN guaranteed values are valid for a thickness from 5 to 75mm