Page 3 - TS 800

P. 3

➢ Welding process

Any conventional fusion welding method can be used, such as submerged arc

welding (SAW), manual metal arc welding (SMAW), flux core wire arc welding

(FCAW), HIG, MAG (GMAW) and TIG (GTAW)

Interpass temperature should be limited to a maximum of 200°C (392°F).

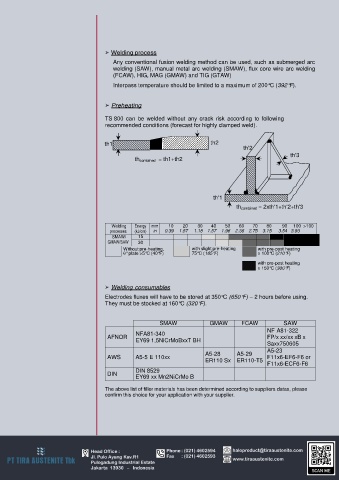

➢ Preheating

TS 800 can be welded without any crack risk according to following

recommended conditions (forecast for highly clamped weld).

th1 th2

th'2

th combined = th1+th2 th'3

th'1

th combined = 2xth'1+th'2+th'3

Welding Energy mm 10 20 30 40 50 60 70 80 90 100 >100

processes (kJ/cm) in 0.39 1.57 1.18 1.57 1.96 2.36 2.75 3.15 3.54 3.93

SMAW/ 15

GMAW/SAW 30

Without pre-heating, with slight pre-heating with pre-post heating

θ° plate >5°C (40°F) 75°C (165°F) ≥ 100°C (210°F)

with pre-post heating

≥ 150°C (300°F)

➢ Welding consumables

Electrodes fluxes will have to be stored at 350°C (650°F) – 2 hours before using.

They must be stocked at 160°C (320°F).

SMAW GMAW FCAW SAW

NFA81-340 NF A81-322

AFNOR FP/x xx/xx xB x

EY69 1,5NiCrMoBxxT BH

Saxx750605

A5-28 A5-29 A5-23

AWS A5-5 E 110xx F11x6-EF6-F6 or

ER110 Sx ER110-T5

F11x6-ECF6-F6

DIN 8529

DIN

EY69 xx Mn2NiCrMo B

The above list of filler materials has been determined according to suppliers datas, please

confirm this choice for your application with your supplier.

SUPRALSIM 690 – 26.10.2004 issue – Page 3