Page 2 - TS 800

P. 2

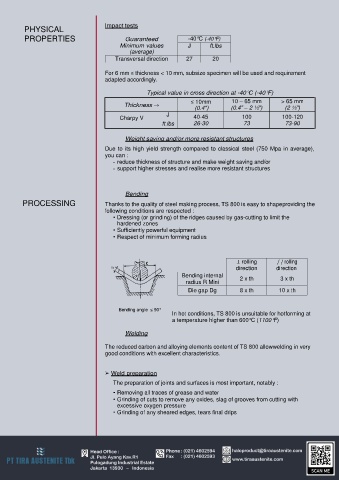

Impact tests

PHYSICAL

PROPERTIES Guaranteed -40°C (-40°F)

Minimum values J ft.lbs

(average)

Transversal direction 27 20

For 6 mm ≤ thickness < 10 mm, subsize specimen will be used and requirement

adapted accordingly.

Typical value in cross direction at -40°C (-40°F) > 65 mm

10 – 65 mm

≤ 10mm

Thickness → (0.4") (0.4" – 2 ½") (2 ½")

Charpy V J 40-45 100 100-120

ft.lbs 26-30 73 73-90

Weight saving and/or more resistant structures

Due to its high yield strength compared to classical steel (750 Mpa in average),

you can :

- reduce thickness of structure and make weight saving and/or

- support higher stresses and realise more resistant structures

Bending

PROCESSING Thanks to the quality of steel making process, TS 800 is easy to shape providing the

following conditions are respected :

▪ Dressing (or grinding) of the ridges caused by gas-cutting to limit the

hardened zones

▪ Sufficiently powerful equipment

▪ Respect of minimum forming radius

⊥ rolling ⁄ ⁄ rolling

direction direction

Bending internal 2 x th 3 x th

radius R Mini

Die gap Dg 8 x th 10 x th

Bending angle ≤ 90°

In hot conditions, TS 800 is unsuitable for hot forming at

a temperature higher than 600°C (1100°F)

Welding

The reduced carbon and alloying elements content of TS 800 allow welding in very

good conditions with excellent characteristics.

➢ Weld preparation

The preparation of joints and surfaces is most important, notably :

▪ Removing all traces of grease and water

▪ Grinding of cuts to remove any oxides, slag of grooves from cutting with

excessive oxygen pressure

▪ Grinding of any sheared edges, tears final drips

SUPRALSIM 690 – 26.10.2004 issue – Page 2