Page 7 - SD 2507Cu

P. 7

DESIGN Cost factor considerations

Maximum allowable stresses given by several pressure vessel codes are shown

here. The high mechanical properties of SD 2507Cu allow thickness and,

consequently, cost reductions..

We are happy to offer assistance in evaluating potential cost savings related to

pressure vessel or structural design and the excellent corrosion resistance

properties of SD 2507Cu.

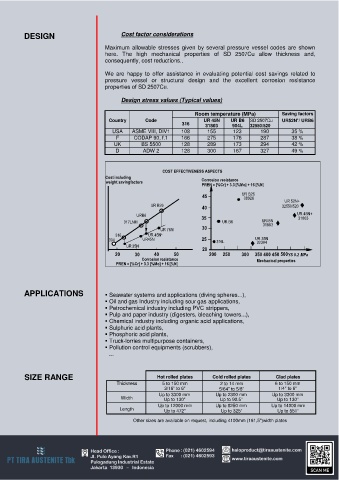

Design stress values (Typical values)

Room temperature (MPa) Saving factors

+

Country Code 316 UR 45N UR B6 SD 2507Cu UR52N / URB6

31803

904L

32550/520

USA ASME VIII, DIV1 108 155 123 190 35 %

287

166

176

CODAP 90, f.1

F

275

38 %

UK BS 5500 128 289 173 294 42 %

D ADW 2 128 300 167 327 49 %

Cost including COST EFFECTIVENESS ASPECTS

weight saving factors Corrosion resistance

PREN = [%Cr] + 3.3 [%Mo] + 16 [%N]

45 UR B26

UR B26 40 08926 32550/520

UR 52N+

URB6 UR 45N+

317LNM 35 UR B6 UR45N 31803

31803

316 UR 45N UR 76N 30

+

304 UR 35N UR45N 25 316L UR 35N

32304

20 30 40 50 20 200 250 300 350 400 450 500YS 0.2 MPa

Corrosion resistance

PREN = [%Cr] + 3.3 [%Mo] + 16 [%N] Mechanical properties

APPLICATIONS Seawater systems and applications (diving spheres...),

Oil and gas Industry including sour gas applications,

Petrochemical industry including PVC strippers,

Pulp and paper industry (digesters, bleaching towers...),

Chemical industry including organic acid applications,

Sulphuric acid plants,

Phosphoric acid plants,

Truck-lorries multipurpose containers,

Pollution control equipments (scrubbers),

...

SIZE RANGE Hot rolled plates Cold rolled plates Clad plates

Thickness 5 to 150 mm 2 to 14 mm 6 to 150 mm

3/16" to 6" 5/64" to 5/8" 1/4" to 6"

Up to 3300 mm Up to 2300 mm Up to 3300 mm

Width Up to 130" Up to 90.5" Up to 130"

Up to 12000 mm Up to 8250 mm Up to 14000 mm

Length Up to 472" Up to 325" Up to 551"

Other sizes are available on request, including 4100mm (161,5")width plates