Page 1 - SH 253

P. 1

PRODUCT DATA SHEET

Corrosion Stainless Steel

HEAT RESISTANT STAINLESS STEEL

SH 253 grade is a fully austenitic stainless steel containing 21 Cr, 1.7 Si, 0.17 N

and Rare Earth elements (Cerium, Lanthane,...) which make the alloy

particularly well designed for high temperature applications.

The nitrogen additions stabilize the austenitic microstructure, particularly at high

temperatures. The alloy is less susceptible to embrittlements effects occuring after

long term exposure. Creep properties are enhanced, due to high Chromium and

Nitrogen. Rare Earth elements (Ce, La,...) are added in order to anchor the oxide

protective film and improve the resistance of the steel to oxide spaling. As a

result, the alloy is much more resistant to high temperature thermal cycling effects

in oxidizing atmospheres compared to SH 310.

SH 253 grade may be used up to 1100°C (2012°F in oxidizing environments.

Thermal cycling effects, sulphur containing atmospheres and low oxygen contents

reduce the high temperature resistance of the steel.

STANDARDS EN 10095 ...................................... X9 Cr Ni Si N Ce 21-11-2 -1.4835

AFNOR.......................................... (Z10 CNS 21 11)

DIN ................................................ W.Nr 1.4835

ASTM. ........................................... UNS S 30815

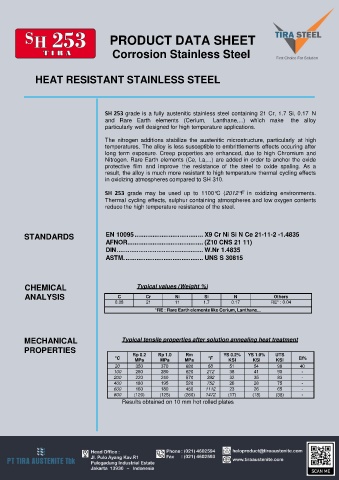

CHEMICAL Typical values (Weight %)

ANALYSIS C Cr Ni Si N Others

0.08 21 11 1.7 0.17 RE* : 0.04

*RE : Rare Earth elements like Cerium, Lanthane...

MECHANICAL Typical tensile properties after solution annealing heat treatment

PROPERTIES

Rp 0.2 Rp 1.0 YS 0.2% YS 1.0% UTS El%

KSI

KSI

KSI

MPa

MPa

680

100 620 212

200 570 392

400 520 752

600 450 1112

800 (120) (125) (260) 1472 (17) (18) (38)

Results obtained on 10 mm hot rolled plates