Page 2 - SA 304

P. 2

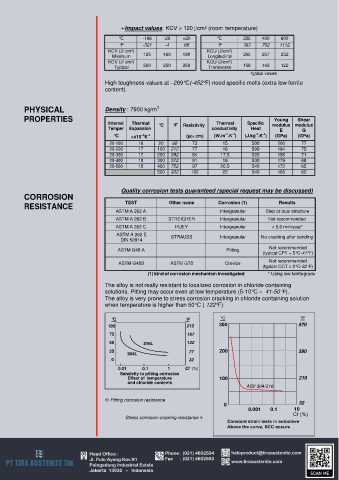

+Impact values KCV 120 j/cm² (room temperature)

°C -196 -20 +20 °C 400 600

°F -321 -4 68 °F 752 1112

KCV (J/ cm²) KCU (J/cm²)

Minimum 125 160 180 Longitudinal 257 252

KCV (J/ cm²) KCU (J/cm²)

Typical 220 250 250 Transverse 142 122

typical values

High toughness values at –269°C(-452°F) need specific melts (extra low ferrite

content).

PHYSICAL Density : 7900 kg/m

3

PROPERTIES Young Shear

Thermal

Interval Thermal °C °F Resistivity conductivity Specific modulus modulus

Temper Expansion

Heat

G

E

-1

-1

-1

-1

- 6

-1

°C x10 K (µ cm) (W.m .K ) (J.kg .K ) (GPa) (GPa)

68

20

20-100 16 100 212 73 15 500 200 77

17

77

16

194

75

500

20-200

20-300 17 200 392 84 17.5 520 186 71

179

91

300

18

68

572

19

530

20-400

20-500 18 400 752 97 20.5 540 172 65

500 932 102 22 540 165 62

Quality corrosion tests guaranteed (special request may be discussed)

CORROSION

RESISTANCE TEST Other name Corrosion (1) Results

ASTM A 262 A Intergranular Step or dual structure

ASTM A 262 B STREICHER Intergranular Not recommended

ASTM A 262 C HUEY Intergranular < 0,6 mm/year*

ASTM A 262 E STRAUSS Intergranular No cracking after bending

DIN 50914

Not recommended

ASTM G48 A Pitting

(typical CPT = 5°C-41°F)

Not recommended

ASTM G48B ASTM G78 Crevice

(typical CCT 0°C-32°F)

(1) kind of corrosion mechanism investigated * Using low ferrite grade

The alloy is not really resistant to localized corrosion in chloride containing

solutions. Pitting may occur even at low temperature (5-10°C – 41-50°F).

The alloy is very prone to stress corrosion cracking in chloride containing solution

when temperature is higher than 50°C ( 122°F).

°C °F

100 212 570

75 167

50 316L 122

25 77 390

304L

32

0.01 0.1 1 Cl (%)

-

Sensivity to pitting corrosion

Effect of temperature 210

and chloride contents

AI SI 30 /316

Pitting corrosion resistance

32

Stress corrosion cracking resistance